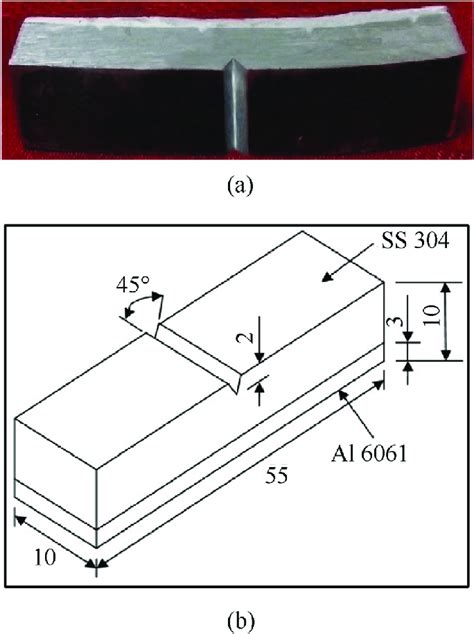

charpy impact test results table|charpy impact test calculator : purchasers Charpy impact strength shows approximately 60% improvement in value for the joints, which was prepared by using beam oscillation whereas 20% reduction for higher welding speed condition.

Resultado da Japa photos & videos. EroMe is the best place to share your erotic pics and porn videos. Every day, thousands of people use EroMe to enjoy free .

{plog:ftitle_list}

Resultado da 5 de out. de 2023 · ONLYFANS. Influencer que recebeu Pix para não fazer plástica revela recorde sexual: “13 horas direto” Emily Ferrer fez .

According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy (KV) results from partially fractured test specimens can be averaged with the results .Charpy impact test results can be shown in Table 2. The thicker specimens show better impact properties at room tem- perature conditions than thinner specimens, according to these.

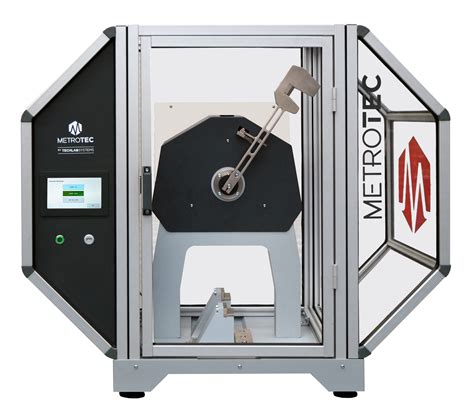

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact .Figure 2-1: Charpy impact tester, sample positioned in anvil and general testing results. This test has been used almost exclusively with body-centered-cubic (bcc) crystalline materials. .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa.

Charpy impact strength shows approximately 60% improvement in value for the joints, which was prepared by using beam oscillation whereas 20% reduction for higher welding speed condition.Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .

The purpose of the impact test is to assess the response of a known material, such as polymers, ceramics, and composites when subjected to sudden stress. It specifically evaluates the toughness, brittleness, notch .

Material impact toughness can be measured by various types of test such as the Charpy V-notch impact test, Izod test or K IC test. The most commonly used test is the Charpy impact test .Guidelines for specifying Charpy V-notch impact prescriptions in steel specifications. Buy. Follow. Table of contents. Figures. Impact testing is required for many critical applications in the construction, machinery and equipment, defense, and energy markets. Charpy testing provides data needed to ensure the quality and reliability of structural .

Figure 2-1: Charpy impact tester, sample positioned in anvil and general testing results. This test has been used almost exclusively with -centered-cubic (bcc) crystalline body materials. These materials show a transition from ductile to brittle behavior with temperature (Figure 2-2). This means that at low temperature the fracture energy is low.

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is .Test results, especially in Europe, may be reported as energy lost per unit cross-sectional area (J/m 2 or ft-lb/in 2). What are the test methods to measure toughness? Test methods used to measure Notched Izod Impact (or notch sensitivity) and Charpy Impact in plastics are: ASTM D256-10(2018): Plastics — Determination of Izod pendulum impact .Computing UnCertainty for Charpy Impact Machine Test Results Before valid Charpy measurements can be made in the laboratory, the machine needs to pass both direct and indirect verifi cation tests as specifi ed in ASTM E 23 [1]. Even if a Charpy machine has passed the indirect verifi cation test, it is likely that results forThe Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. . It should be emphasised that Charpy tests are qualitative, the results can only be compared with each other or with a requirement in a .

The objective of the Charpy impact test to ISO 148-1 is the determination of the impact energy and determination of the impact strength of a metal. The test indicates whether the metal is tough or brittle. In addition, the tough/brittle transition can be determined based on the temperature. Impact strength is a material characteristic value.

Download Table | Charpy Impact Test Results for the Weld Metals. from publication: Low temperature impact toughness of structural steel welds with different welding processes | Influence of .The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away from the pendulum hammer and is placed exactly across from the point at which the hammer strikes the specimen.Contents 1.Introduction 2.UncertaintyofaTestResult 3.TypeBUncertaintyEvaluation 4.MachineBias 5.DirectVerification 6.Temperature 7.ExpandedUncertainty 8.Examples 8 .

Download Table | Charpy V-notch impact test results from publication: Comparative experimental study of hot-formed, hot-finished and cold-formed rectangular hollow sections | This paper presents a .

Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test.

Randy K, Nanstad' and Mikbail A. Sokolov' cHARPY IMPACT' TEST RESULTS ON FIVE MATERIALS AM) NIST WRIETCATXON SPECIMENS USING INSTRUMENTED 2-mm AND 8-mm STRIKERS REFERENCE: Nanstad, R. IC, and SokoIov, M. A, "Charpy Impad Test Results on Five Materials and MST Veri€ication Spechnens Using Instrumented 2-mm and 8-mm .An impact test consists of a striker hitting the test specimen to transfer a large force in a short time.You can use a drop tower or a pendulum tester to achieve such large forces.. A striker is dropped vertically from a height for a drop tower test and uses gravity to achieve the necessary impact energy. Similarly, in a pendulum test, the striker is fixed to an arm that swings like a . The Heavy-Section Steel Irradiation Program at Oak Ridge National Laboratory is involved in two cooperative projects, with international participants, both of which involve Charpy V-notch impact tests with instrumented strikers of 2mm and 8mm radii.

Computing UnCertainty for Charpy Impact Machine Test Results Before valid Charpy measurements can be made in the laboratory, the machine needs to pass both direct and indirect verifi cation tests as specifi ed in ASTM E 23 [1]. Even if a Charpy machine has passed the indirect verifi cation test, it is likely that results for A Charpy impact test (CVN test) is used to measure the fragile-ductile temperature and as a quality control test. This evaluation's simplicity allows converting energy values to fracture toughness . Charpy impact test results are measured in joules, the SI unit for energy. This is simply the amount of work performed by a 1-newton force pushing a sample by 1 m in the direction of the force. This value can be used to calculate the impact energy in J/m2 by dividing the joule value by the sample's cross-sectional area at the sample notch.

Download Table | Charpy test results (Charpy impact energy). from publication: Study of Resistance Spot Welding Between AISI 301 Stainless Steel and AISI 1020 Carbon Steel Dissimilar Alloys .Table of contents. Foreword. 1 Scope. 2 Normative references. . 4.5 The Charpy V-notch impact test as a powerful tool for delivery control in steel specifications. 5 Information to be gained from the impact test. . 7.4 Interpretation of test results. Bibliography. Figures? Redlines ? Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered.

charpy impact tester

Standard E 23, ―Standard Test Methods for Notched Bar Impact Testing of Metallic Materials‖. In 1901, a French researcher named Charpy published his work—the second publication in the world on pendulum machine testing—on notched bar pendulum impact tests [2]. Charpy’s tests used a pendulum impact machine based on the design developed .

ASTM A370 Table 9. Table 9 is based on a simple thickness-ratio . Correlation of Charpy Test Results for Standard and Nonstandard Size Specimens. Welding Research Supplement, pp. 385-393. 14-200 -100 0 100 200 300 400 0 5 10 15 20 25 30 35 40 45 50. 10 7.5 5 2.5. KV. 10est [J] T. adjusted [o. C] 4340 low toughness. Enrico Lucon, C. N. (2015 .Download Table | Charpy Impact Test Results from publication: Investigation of Mechanical and Electrical Properties of Kevlar/E-Glass and Basalt/E-Glass Reinforced Hybrid Composites | Composite . The results show that pendulum velocity has negligible influence on Charpy impact test results; the maximum force and impact absorbed energy both have a highly linear relationship to specimen width; Charpy impact test is sensitive to striker geometry, the results measured by 2 mm-striker are obviously smaller than those of 8 mm-striker.

𝛽 = Maximum angle of pendulum after release The results of the Charpy impact test indicate the energy absorbed by the material specimens increases as the temperature of the specimen increases, as indicated numerically below in Table 1, and graphically in Figure 3. . , and graphically in Figure 3. Table 1. Results g 9/s 2 80 °C β 65 .

Many engineers were interested in Charpy test for metallic materials [11,28,29,30], but nowadays this test, in classical or modified configuration, becomes useful to be done for other materials, including polymers, composites [], and ceramics [].Simulation of such a test is useful for understanding the material behavior under impact load, and when knowing .

Gas Permeability Tester online sales

Gas Permeability Tester mail order

Resultado da Envie-nos uma mensagem, vamos responder o mais rápido possível. O Grupo Fatal Model é uma companhia brasileira de tecnologia e serviços .

charpy impact test results table|charpy impact test calculator